Description

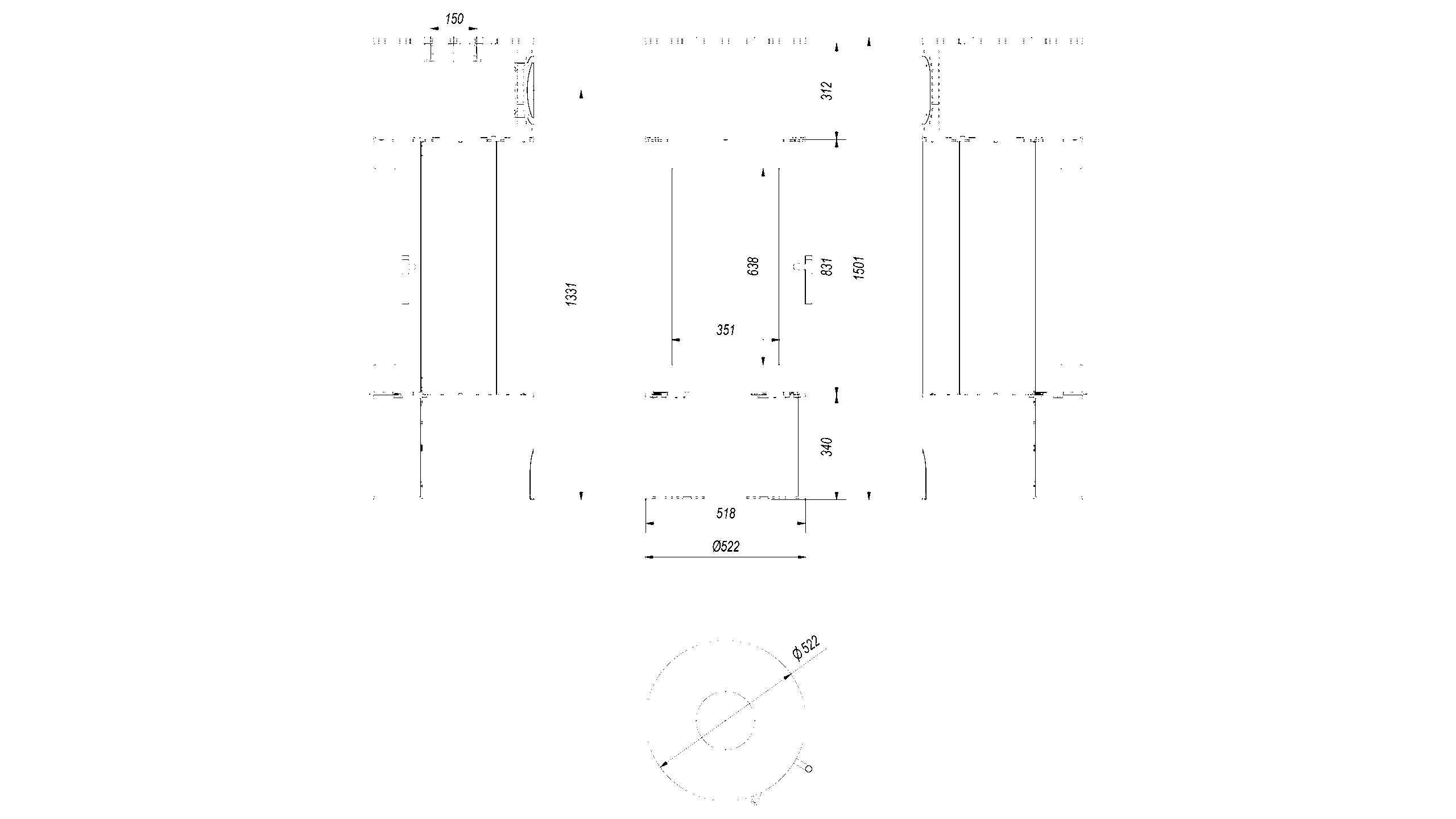

Technical Specifications

Features

MODERN DESIGN

The spacious glazing makes the vision of fire more attractive. The interior of the stove is lined with innovative material Acumotte which perfectly contrasts with the stove, giving it a modern design. Acumotte is a ceramic material which accumulates heat and raises the temperature in the furnace.

Solid vertical handle, makes it easy to seal the door. Due to this, the appliance is suitable for the homes with recuperation.

Under the combustion chamber there is an additional, closed chamber, in which the air inlet connection system is hidden. Opening the chamber door is based on an intuitive click-to-click system that does not require an additional handle.

MAXIMUM USE OF ENERGY

More efficient combustion and longer maintenance of temperature by lining the combustion chamber with ceramic material Acumotte which accumulates heat and raises the temperature in the furnace.

Full combustion on the dust thanks to deflector which extend the exhaust path. This process increases the efficiency of burning and guarantees better energy use. It also minimizes the emission of harmful substances to the atmosphere. Additionally a diphragm installed at the exhaust outlet functions similarly to the deflector , enhances the effeciency of the device.

Primary air is supplied to the insert thanks to the built-in 100 mm external air inlet. Air inlet is located from the bottom of the insert. Insert has a cover plate on the back wall and a hole in its base. Thanks to it the user can choose how to connect the external air kit. Air adjustment is done with a throttle adjustable by one regulator placed below the door. This solution prevents from improper usage. Whole mechanism works quietly and efficiently.

The insert has been equipped in triple air system of combustion chamber. Primary air which enables setting a fire is supplied under the grate. Secondary air – providing economic and ecological burning is supplied by holes on the back wall.

Additionally, this insert is equipped with Clean Glass System (air curtain), so the air is supplied directly to the glass through a system of channels located on the sides of the fireplace. In this way oxygen is supplied to the upper part of the combustion chamber, were happens post-combustion of gases produced while combustion of wood what at the same time reduces harmful CO emissions to the atmosphere.

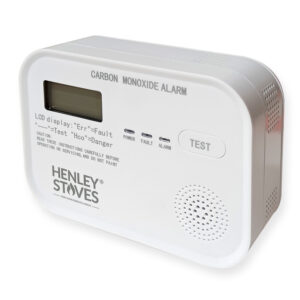

SAFETY AT THE HIGHEST LEVEL

The ANTARES front is equipped with heat-resistant ceramics that withstand temperatures up to 800°C. The glass we propose is certified for quality and safety.

The body and front of the insert are resistant to high temperatures due to the use of high-grade steel. They also ensure the stability of the entire structure.

Excellent tightness of the device is ensured thanks to solid welds made in the noble gas shield. Steel elements are laser cut using modern devices and then bent on CNC bending machines.

COMFORTABLE USE

The stove uses a specially profiled bottom plate made of Acumotte, thanks to which the combustion chamber is deeper and contains more wood.

The furnace can easily be kept clean thanks to the removable grate and container in which ash is collected.

The glazing stays clean thanks to the clean glass system used in it.

The air curtain separates the glass from the firebox. Thanks to that it does not get dirty

ECOLOGICAL COMBUSTION

The stove meets the criteria of Ecodesign and the restrictive BImSchV 2 norm setting the maximum CO emission.

Reviews

There are no reviews yet.