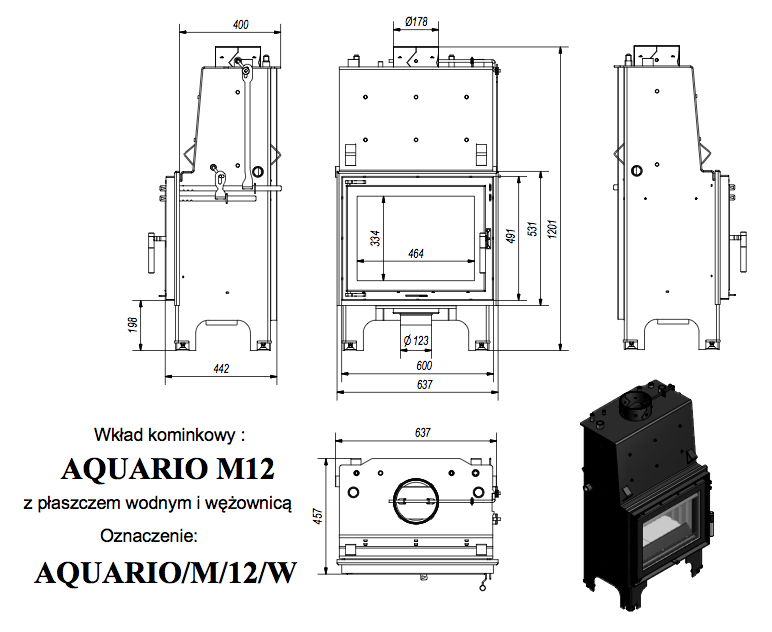

Description

| Rated power (kW) | 12 |

| Power to the water | 8.1 |

| Flue diameter (mm) | 180 |

| Efficiency % | 86.7 |

| CO emission (after 13% CO) | 0,09% |

| Exhaust gas temperature C | 198 |

| Operating pressure BAR | 2 |

| Weight (kg) | 236 |

| Heated m² ** | 80-140 |

| Max. wood length (mm) | 450 |

| Housing | Steel 5 mm |

| Fuel Types | Deciduous wood |

Aquario – new Fireplaces with water heating coil. The used technology and materials to create an efficient, cost-effective and environmentally friendly high efficiency (about 85% ) the capsule, the release of low-CO emissions.

Therefore capsules parameters meet strict German standards BImSchV 1 and 2 BImSchV, which are among the most stringent in Europe. Eco Aqua line of capsules made of boiler steel, so it is reliable, heat-resistant and long lasting. They are adapted to the operation of central heating systems with a working pressure up to 2 bars. Standard capsules fitted coil that thermally protects the machine. Water circuit connector body is additionally strengthened. Optionally offered with double glass capsule, the so-called “glass” system, with black painted glass edges looks modern. The combustion chamber is lined with “Acumotte” ceramic plates. This material is characterized by both accumulation and insulating properties. Insulation- limiting the immediate impact of the capsule body heat increases the temperature of the combustion chamber and reduces gas emissions into the environment. Accumulates – accumulates during combustion to generate heat, which is excreted slowly for several hours, the flame go out. Eco Aqua fireplaces adapted to work with central heating systems, heat pumps, solar batteries with domestic hot water boilers and STORAGE TANKS.

Security.

Standard equipped with a coil in capsules, which prevents the heat and the hot water loop body is additionally strengthened connections.

Use and operation of the coil:

Eco Aqua encapsulated coil is built into the fireplace ½ inch diameter copper tube to protect the water system from overheating. In other words, performs the function of the fireplace cooler and valid from a thermal safety valve.

Water circuit installed in the upper part of nozzles for supplying water from the serpentine water supply. Connect with ½ inch external thread consists of the coil ends.Connect with ½ inch internal thread for the connection of the safety valve heat sensor, which controls the release of water through the coil. If the central heating system takes less than a fireplace heat generated power, water temperature water circuit can lead to dangerously. In such cases, in excess of 97 C, and when the thermal valve opens the cold water from the water passage through the coil and this water cools the water in the water circuit.

Environmentally-friendly.

Air entering the combustion chamber is controlled in two ways:

– Regulates the primary air supply in the ash drawer into the combustion chamber, regulates air quality is burning intensity.

– regulates the secondary air supply through the rear panel. This weather is responsible for the burning of the exhaust gas. This limits the harmful substances in the environment and increase the efficiency of the capsule.

– This solution provides very good focal CO emission parameters.

Deflector system:

-Two-Pots: steel and vermiculite called smoke shelf fitted in the upper part of the fireplace capsule. They extend the exhaust gases.

Valve System:

– Two valves: damper upper and lower exhaust valves control the output.

– Built-in fireplace is in the lower part of the valve. Fitted above the combustion chamber and the deflector continued over its entire length. When you open it in the initial phase of the combustion exhaust gas path to the short stack, so it automatically increases traction. After closing the valve, the exhaust gas is directed between the deflector and the vertical cylinder. Therefore, between the deflector and the steel deflector arising from space burns in the combustion chamber unburned fuel residues. It provides additional heat is transferred to the vertical heater tubes and the water circuit (water system). This greatly increases the focus performance values (from 82% to 87%)

– other (upper) rotary valve, built-in fireplace flues, allows you to adjust chimney traction.

Settings.

The combustion chamber is lined with “Acumotte” ceramics, which increases the temperature in the combustion chamber and improves the combustion parameters.In addition, the back of the swing system atsakkko air supply for the combustion chamber and the secondary air-.

Secondary air supply through the rear panel is responsible for the burning of fuel residues and reduces harmful substances into the environment, and improve the performance of the liner. This solution provides excellent fireplaces CO emission parameters.

Power and Performance.

Special water loop system allows to extract from the exhaust gas and heating system to transfer large amounts of heat, thus generating a large focal energy efficiency, reaching up to 85%.

Heat circulation takes place in the upper part of the capsule, and a vertical loop water heater. It is a system of vertical tubes. These tubes increases water heated by contact with the material, ie, the emission area. Tubes task – to extract heat energy contained in the combustion chamber of the capsule come out of the exhaust gases. Hot exhaust gases pass through the tubes and heats the water around them. Warm water is output through the side wall of the fireplace plugged into the central heating system.

Reviews

There are no reviews yet.