Description

Characteristics:

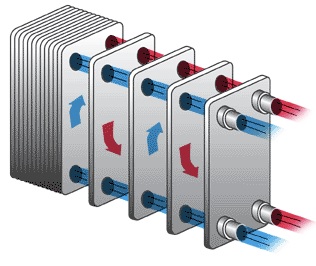

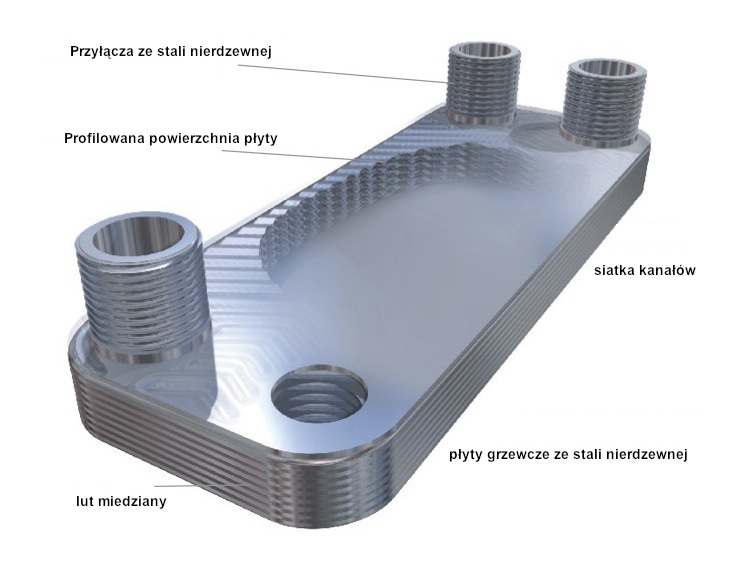

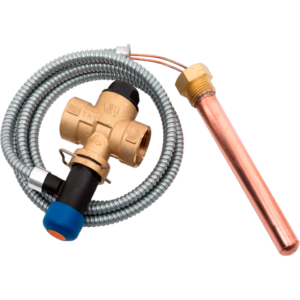

brazed plate heat exchangers are flow devices, countercurrent. A heat exchange surface formed

corrugated stainless steel plates together in a package with solder, a copper or nickel. The flow of fluids exchanging

heat is directed in every second channel formed by the heating plates. Exchangers are made entirely of stainless steel

as a construction undecomposable. Tightness construction and permanent fixation plates provides process of brazing in a vacuum furnace.

Special profiling heating plates ensures the flow of high turbulence. This allows a very efficient heat transfer

and prevents the accumulation of dirt inside the heat exchanger. The choice of plate heat exchanger depends on the power of the fireplace, which has been selected. Exchanger 15 plate can be used for fireplace inserts with a capacity of up to 15 kW.

Advantages: – High heat transfer coefficient – small dimensions at high power heating – high resistance to changes in pressure and temperature – change in the number of plates and duct system allows you to customize the device to your individual needs – Simple installation and dismantling materials: – plates and connections: stainless steel – brazing copper and nickel

Application: – Central heating – heating domestic hot water – solar heating systems, geothermal – heat transfer in industrial processes – condensers and evaporators for heat pumps – industrial cooling plants (oil coolers) – Refrigeration

Reviews

There are no reviews yet.